Tag UHF vs tag NFC : quelles différences ? Que choisir ?

Lire la suite de l'article >

Performance, simplicité, polyvalence : nos trois nouveaux lecteurs AX'Up sont prêts à transformer votre quotidien professionnel. Explorez la gamme dès maintenant !

Découvrir la gammeSolutions innovantes

Fonctionnement

A propos

Fort de son expérience en tant que leader de la technologie RFID. AXEM Technology se positionne comme un partenaire de choix pour améliorer la gestion et la traçabilité de vos équipements de protection individuelle (EPI).

Travailler avec nos experts RFID c’est choisir :

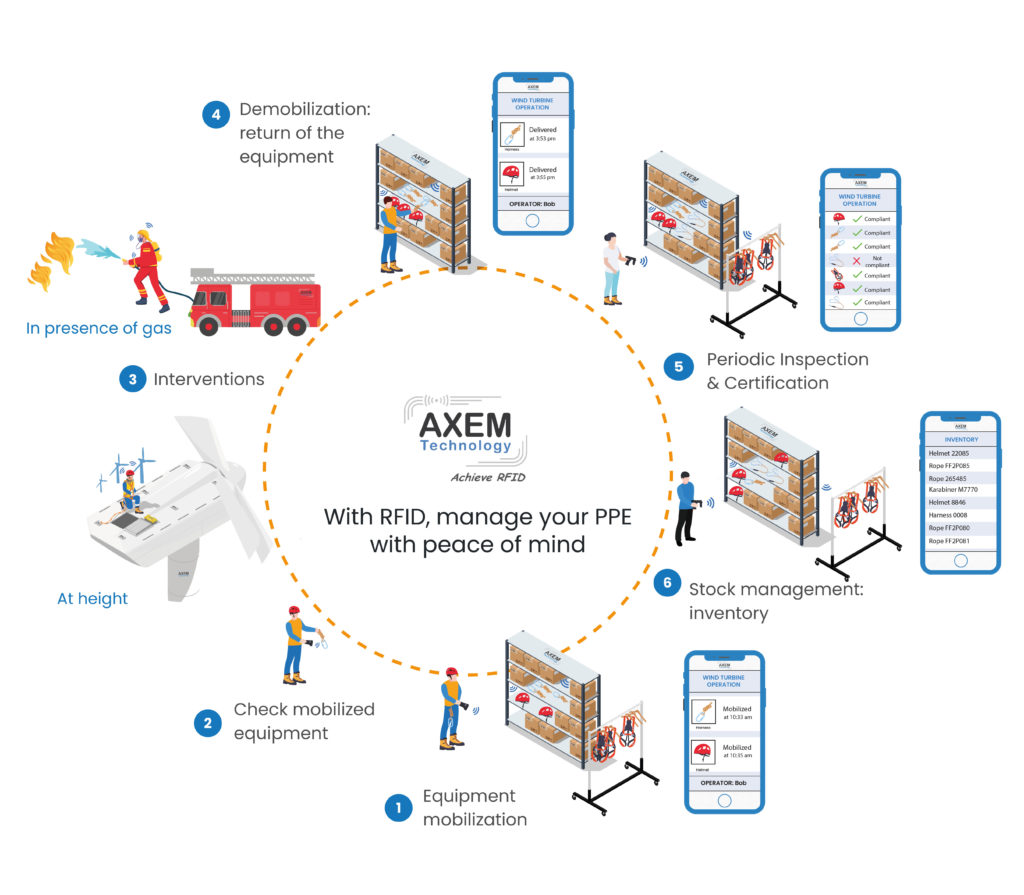

Procédure

Choisissez le tracking EPI intelligent avec la technologie RFID. Apprenez à choisir et fixer les tags RFID sur divers types d’Équipement de Protection Individuelle. La garantie d’une traçabilité des vêtements de travail, casques de protection, harnais anti-chute, mousquetons… Le marquage RFID EPI garantit un inventaire des vêtements de protection et tout autre type d’EPI, fluide et maîtrisé.

Applications

Assurez un suivi optimal des Équipements de Protection Individuelle avec la technologie RFID. Quelle que soit votre activité. Les solutions RFID proposées par AXEM Technology répondent aux besoins des secteurs les plus exigeants et des métiers variés : travailleurs sur chantier, agent hospitalier, militaire, pompier, agent d’entretien, électricien…

Grâce à nos tags et étiquettes RFID UHF (Ultra Haute Fréquence), la gestion des EPI devient plus simple et précise. Que vous soyez dans la logistique, l’industrie ou la sécurité. Nos solutions vous permettent de respecter les normes et réglementations en matière d’EPI.

La traçabilité en temps réel offerte par la RFID facilite le suivi de la maintenance, de l’inventaire et du contrôle des EPI. Ainsi, vous pouvez assurer la conformité de vos équipements de protection individuelle tout en optimisant votre chaîne logistique et votre gestion des stocks.

Adoptez la technologie RFID pour une gestion efficace et personnalisée de vos flux EPI. Bénéficiez d’un suivi actif et rigoureux, adapté aux besoins de votre secteur d’activité et de vos métiers spécifiques.

Notre offre

La technologie RFID constitue un pilier essentiel pour optimiser la gestion des équipements de protection individuelle (EPI). Renforcez la sécurité et l’efficacité des travailleurs au sein de votre entreprise ou collectivité.

AXEM Technology vous propose une gamme étendue de solutions RFID logistique spécifiques aux EPI : dispositifs d’antennes RFID, tags et étiquettes RFID, modules de lecture RFID industriels, terminaux mobiles RFID UHF, lecteur RFID autonome…

Découvrez comment la technologie RFID et la traçabilité en temps réel peuvent apporter un véritable avantage compétitif à l’inspection des EPI. Améliorant leur suivi, leur maintenance et en garantissant une conformité réglementaire maximale.

Téléchargez notre offre RFID pour la traçabilité des vêtements de travail et tout autre équipement de protection des travailleurs.

Nous travaillons avec un réseau de partenaires de confiance qui proposent des solutions logicielles et qui interviennent chez nos clients pour l’intégration de nos matériels. Contactez-nous afin que nous vous mettions en contact avec le partenaire le plus proche de chez vous.

FAQ

La technologie RFID offre une traçabilité simplifiée, fiable et sécurisée des EPI, facilitant ainsi leur suivi. Chaque équipement de protection individuelle est équipé d’une puce RFID contenant toutes les informations pertinentes telles que le numéro unique, la date de fabrication, le modèle, le fabricant, l’état, la dernière opération de maintenance ou inspection des EPI ou encore la localisation.

Ces données sont également enregistrées dans une base de données centralisée. Assurant une gestion numérique améliorée et un accès rapide aux informations essentielles. Cette solution innovante et avantageuse facilite grandement la vie des utilisateurs et des distributeurs d’EPI, en garantissant une meilleure organisation et un suivi efficace.

Les systèmes de suivi RFID réduisent ainsi les erreurs humaines, optimisent la gestion des stocks et garantissent une meilleure traçabilité et conformité aux normes de sécurité.

Pour choisir entre la technologie RFID UHF et NFC pour l’identification et la traçabilité de vos EPI, il est important de prendre en compte les spécificités de chaque technologie. La RFID (Radio Frequency Identification) est un système d’identification sans fil qui utilise des ondes radio pour transférer des données entre une étiquette et un lecteur.

La RFID UHF permet une identification aisée des équipements de protection individuelle et est idéale pour effectuer des inventaires rapides grâce à sa capacité de scan multiple. La mobilisation et la démobilisation des EPI sont également très rapides avec un lecteur UHF, ce qui assure un gain d’efficacité dans toutes les tâches. Les inventaires de matériel peuvent être réalisés en quelques secondes seulement.

La NFC (Near Field Communication) est une autre technologie de communication sans fil qui permet d’échanger des données entre deux dispositifs à courte distance. Elle permet aux opérateurs de vérifier que le matériel qu’ils vont utiliser est bien certifié et a été vérifié. Toutefois, l’opération de scan est plus longue et moins intuitive avec la NFC, et cette technologie ne permet pas de réaliser des inventaires.

Pour marquer vos EPI avec la technologie RFID, vous devez associer un numéro unique à chaque équipement, enregistré dans la mémoire d’une puce RFID.

Cette puce se trouve dans un tag RFID ou une étiquette fixé(e) sur l’EPI. Plusieurs méthodes de fixation sont disponibles, comme la colle, les clips, les gaines thermo-rétractables ou l’adhésif.

Il est essentiel de choisir un identifiant RFID adapté aux contraintes environnementales auxquelles l’EPI sera exposé. Assurant ainsi une identification et traçabilité fiable et durable.

Déploiement de la digitalisation de votre entreprise.

La technologie RFID révolutionne la gestion des EPI en numérisant toutes les données associées.

Cette méthode offre un suivi fiable et performant, en permettant un accès instantané aux informations sur les stocks, l’utilisation des EPI et les contrôles à effectuer.

Les puces RFID sont conçues pour résister aux conditions exigeantes des EPI, garantissant ainsi une traçabilité durable et robuste.

Pour garantir la sécurité et la confidentialité des données RFID des EPI, il est essentiel de prendre des mesures de protection adéquates. Tout d’abord, la puce RFID ne contient qu’un identifiant unique, similaire à un code-barres, sans aucune information personnelle. De plus, il est possible d’ajouter un mot de passe ou de chiffrer les données pour renforcer la protection contre les atteintes à la confidentialité et les attaques de sécurité.

La RFID contribue à garantir une meilleure conformité réglementaire en matière d’EPI. Digitalisant et centralisant les informations relatives aux opérations de maintenance et d’inspection dans une base de données.

Ce système facilite la gestion des contrôles grâce à un système d’alerte. Il empêche la mobilisation des EPI non inspectés avant d’avoir passé l’inspection périodique requise.

L’historique complet des opérations effectuées sur les EPI est facilement accessible d’un simple clic. Permettant une traçabilité optimale et une conformité renforcée.

Les avantages de la solution RFID pour l’inventaire des EPI sont nombreux :

Grâce à la technologie RFID, les contrôles et vérifications périodiques des EPI sont consignés de manière fiable et précise dans une base de données. Ainsi, l’historique des opérations effectuées sur chaque EPI est accessible en un clin d’œil, réduisant les risques d’erreur. En garantissant un suivi rigoureux des EPI, la RFID renforce la protection des travailleurs qui les portent ou les utilisent, assurant leur sécurité au quotidien.

Le choix du tag RFID le plus adapté pour vos EPI dépend de plusieurs critères tels que la forme, les dimensions et le mode de fixation. Chez AXEM Technology, nous avons collaboré avec des experts du secteur pour sélectionner des tags spécifiquement conçus pour chaque type d’EPI. N’hésitez pas à nous contacter afin de recevoir des conseils personnalisés pour choisir le matériel de marquage RFID le plus approprié pour vos équipements.

AXEM Technology est votre allié pour l’implémentation réussie de la technologie RFID dans la gestion de vos EPI. Notre expertise couvre :

Nous sommes à vos côtés pour :

Faites confiance à AXEM Technology pour des solutions RFID de haute qualité, améliorant l’efficacité, la traçabilité des équipements de Protection Individuelle et la productivité. Contactez nos experts RFID et nous vous mettrons en relation avec le partenaire le plus proche de chez vous.

Le blog

Tag UHF vs tag NFC : quelles différences ? Que choisir ?

Lire la suite de l'article >Traçabilité des équipements avec la RFID Casques, combinaisons, gants, mousquetons, cordes, harnais… Les EPI[1] sont des éléments essentiels lors de l’intervention des travailleurs sur des opérations à risques. Afin d’assurer la sécurité des professionnels, leur équipement doit être...

Lire la suite de l'article >