May 2, 2023

Which RFID tag for industrial laundry?

The gradual introduction of RFID technology has enabled optimized identification and traceability of flat linen and workwear throughout the washing cycle. This is made possible, on the one hand, by an RFID tag attached to the linen and integrating information, and, on the other hand, by an RFIDReader which reads and transmits this data. This technology enables fast, error-free monitoring of laundry management.

Discover in this video how an RFID system works in an industrial laundry.

Laundry is a harsh environment for RFID tags

Tags used in laundries are specifically designed to cope with harsh conditions such as multiple washes, chemicals, high pressure spin drying and laundry ironing. The tag’s functionalities must be able to remain intact even after more than 50 washes and high pressure during spin drying.

How to choose your laundry RFID tag?

Choosing a tag is not easy because there are several types of textile tags with different characteristics to best meet your needs.

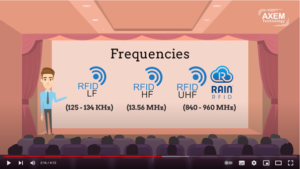

The choice of the frequency of an RFID tag

- Low Frequency Tags (LF)

- High Frequency Tags (HF)

- Ultra-High Frequency (UHF)

These frequencies meet the constraints of distance and speed of reading.

The important thing to remember is that LF tags have a lower data transmission capacity but the reading capacity increases in the vicinity of metals and liquids. Tags that operate with a higher frequency allow for faster data transmission and greater reading distance, however the waves are more sensitive to interference caused by the presence of liquids and metals.

UHF allows faster data acquisition at greater distances.

For Know more on the specifics of RFID frequencies, watch this video.

The choice of reading and/or writing the RFID tag

Depending on your needs, the tag's chip can be equipped with a simple read function or a read and write function. The read function allows to read the information contained in the textile tag, while the second one allows to read and insert new information.

The mode of ficxation

There are several methods of attaching the RFID tag to the textile:

- sew it on the textile, for example in the collar of a garment or in a hem

- iron-on using a heat-sealing machine. heat-sealing

It is important to choose the RFID tag with the most suitable fastening method for your textile.

The type of textile to be identified

RFID can identify all types of textiles: workwear, PPE, flat linen, personal clothing. It is important to choose an RFID tag that will last the entire life cycle of the textile. This means that the tag must resist at least the same number of washing cycles as the textile but also the environmental conditions undergone by the linen: heat, pressure, humidity, sterilization...

In the hospital environment, MR conditional compatible RFID chips (1.5T-3T) will be chosen for linen identification. This compatibility means that the RFID tag is adapted to hospital standards and in particular to MRI examinations. Indeed, it does not risk to falsify the medical diagnosis or to alter the patient's health condition.

Just as cleanroom work clothes are made of synthetic fibers that are strong fibers, RFID tags used for identification of this clothing equipment must be free of natural fibers such as cotton, woven from loose fiber. 100% polyester tags are much more suitable.

How to fix the RFID laundry tag?

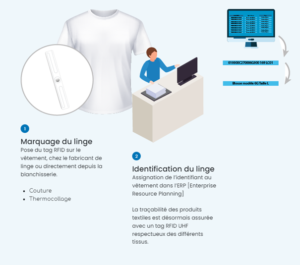

The fixing of a tag on a textile is done in two steps:

- The RFID tag is placed on the textile directly by the textile manufacturer or by the laundry, usually before the first wash cycle of the garment.

- The association of the unique number of the RFID chip with the textile in the ERP [Enterprise Resource Planning].

But, what is the purpose of these tags in the laundry process?

RFID technology enables laundry linen to be identified and traced. For example, an RFID gantry, consisting of RFID antennae and an RFID Reader , positioned in the laundry's reception area, can scan the volume of all soiled linen as it passes through the cart. p

Once washed, wrung out and/or ironed, the linen can be identified again, which allows the operators to know in real time what linen is available in the factory. During the strapping of the batches, the linen can be identified again via an RFID antenna integrated in the strapping machine. This technique allows to identify the linen in order to gather the specific pieces of linen. The linen is then ready to go back to supply customers with clean linen!

This technology also makes it possible to find a lost product. Thanks to a geolocation function and access to the laundry's history, an RFID Mobile Reader can be used to find an item in stock, whether in a laundry, a company, a hospital, a factory, etc.

More globally, RFID allows the optimization of flows: identifying the linen allows to have a real time visibility of the stocks in the factory and at the customer's.

RFID tags are revolutionizing the work of operators in the laundry industry. They save a lot of time, reduce errors and losses, save energy, optimize flows and increase productivity for the laundry.

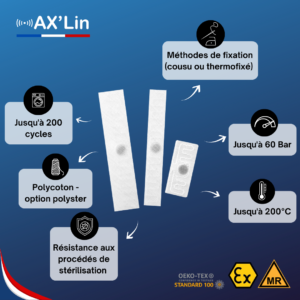

AX'Lin: a new range of RFID textile tags with high added value

AX'Lin flexible RFID tags for laundry identification are designed and manufactured in France. Available in 3 formats, AX'Lin tags withstand the washing conditions of industrial laundries and maintain their reading performance throughout the life of the linen.

AX'Lin tags are resistant to more than 200 industrial washing cycles, to a spin pressure of 60 bars, to a maximum temperature of 200°C and to sterilization processes (autoclave or Gamma rays in option). These tags are 100% cotton-free and compatible with clean rooms.

Our tags are MR Conditional, ATEX and OEKO-TEX Standard 100 certified.

Do not hesitate to contact us to guide you. Together, we will find the RFID tag that will best meet your expectations.